Return to flip book view

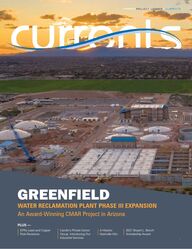

Message PROJECT UPDATE CURRENTS1PLUS —EPA’s Lead and Copper Rule RevisionsA Historic Nashville Win2021 Bryant L. Bench Scholarship AwardCarollo’s Private Sector Group: Introducing Our Industrial ServicesWATER RECLAMATION PLANT PHASE III EXPANSIONAn Award-Winning CMAR Project in ArizonaGREENFIELD

32DRINKING WATERCity of Tampa’s Suspended Ion Exchange (SIX) PilotMELANIE PICKETT , PhD (mpickett@carollo.com) LARRY ELLIOTT, PE, BCEE VINCENT HART, PE TECHNICAL EDITOR: Jess Brown, 714-593-5100 | jbrown@carollo.comCONTENT EDITOR: Nick WebberCOPY EDITOR: Youmi ParkDESIGN AND PRODUCTION: Laura Corrington, Silvia Higuera-Backlund, Matthew ParrottIN THIS ISSUE 2 Preparing for the Lead and Copper Rule Revisions 4 Greenfield Water Reclamation Plant: Process Upgrades and Operational Innovation Make for an Award-Winning CMAR Project 6 Carollo Private Sector Group - Working Closely with Industrial Clients Throughout the US 7 Making History: Nashville Metro KR Harrington and Omohundro WTP Upgrades 8 Bryant L. Bench ScholarshipNICK WEBBER, PE (nwebber@carollo.com)Greetings from your Currents Content Editor! It’s been a great pleasure to work on Currents since its inception!In this issue, we feature the Greenfield Water Reclamation Plant (WRP) in Arizona: a Construction Management At-Risk (CMAR) project that endured technical, construction—and of course—COVID-19-related challenges. All in all, the project was successfully completed at the end of last year and received multiple 2021 Project of the Year awards. Congrats to all of the Greenfield WRP team members!You’ll also read about the EPA’s Lead and Copper Rule updates, a big project win for our new Carollo office in Nashville, the 2021 Bryant L. Bench Scholarship recipient, and an introduction to the industrial client services of Carollo’s Private Sector Group (PSG).I hope you enjoy reading this issue and learning more about Carollo and the water industry. Please contact me or the primary authors if you have any questions or comments. Wishing everyone the best for the remainder of 2021!THIS ISSUE'S EDITORIALCURRENTS IN THIS ISSUEPreparing for THE LEAD AND COPPER RULE REVISIONSThe United States Environmental Protection Agency (EPA) published the Lead and Copper Rule Revisions (LCRR) in the Federal Register on January 15, 2021 (86 FR 4198). The effective date was recently delayed until December 16, 2021, allowing time for the EPA to complete its review of the rule under the new administration, and the compliance deadline has been shifted to October 16, 2024. While the EPA could change the rule, major comprehensive changes are unlikely. The delay provides water systems with the opportunity to get a head start on items that are anticipated to be required under the LCRR.CAROLINE RUSSELL, PhD, PE, BCEE (crussell@carollo.com)COMMENTARY CURRENTSRecommended Next StepsBased on Carollo’s experience helping several water systems develop a LCRR compliance strategy, the following immediate steps are recommended: Develop and adopt a 2024 strategy outlining action items to prepare for the deadline. Develop a schedule, resource plan, and budget to complete the steps outlined in the strategy. Develop a data management plan and define terminology to be used for consistency in the LSL inventory. Start developing the LSL inventory. Review lead and copper sampling sites and any changes needed to comply with the new tiering structure. Start developing a list of schools and childcare facilities and corresponding contact information for notification regarding sampling. Start developing public education materials and associated distribution lists.LCRR Compliance ElementsThe LCRR stipulates that water systems complete the following items by the compliance deadline: Ò Lead service line (LSL) inventory. Water systems must develop an inventory of the materials used in both the publicly- and privately-owned service lines. The inventory must be publicly available, and water systems must notify customers with LSLs, lead-status unknown service lines (LSUSLs), and galvanized pipes that are currently or were previously downstream of lead pipes (i.e., galvanized requiring replacement or GRR). Based on experience from water systems that have completed LSL inventories, this LCRR compliance requirement could take years to complete. Ò LSL replacement plan. Water systems must develop a LSL replacement plan, unless all service lines are confirmed to meet the EPA definition of non-lead pipe. LSL replacement frequency will depend on 90th percentile lead concentrations. Ò Updated list of lead and copper compliance sampling locations. The LCRR establishes a revised tiering structure for lead and copper tap sample locations, and water systems may need to update their sampling plans to reflect these changes. Under the LCRR, single family structures (SFS) and multi-family residences (MFRs) with LSLs must be prioritized as Tier 1 and 2 locations, respectively, for sampling. If additional locations are needed to meet the required number of samples, properties with GRR are selected next (Tier 3 locations), followed by copper pipes installed prior to 1986 (Tier 4 locations), and other representative locations (Tier 5). Ò Revised text on lead for the consumer confidence report. Additional public outreach material that water systems need to have ready to go by 2024 include: Public education (PE) materials for schools and childcare facilities. PE materials for properties with LSLs, LSUSLs, or GRR service lines. PE materials for new locations designated for lead and copper compliance sampling. Ò List of schools and childcare facilities within the service area. While the LCRR requires that sampling only be conducted in elementary schools and licensed childcare facilities, secondary schools should also be included in the list, and contacted, so that they can opt into sampling, if desired.Once the compliance deadline is reached, water systems will need to comply with the new 10 microgram per liter (µg/L) trigger level based on 90th percentile lead concentrations, and “find and fix” requirements for individual lead samples above 15 µg/L. Calcium and blended phosphate will no longer be accepted as corrosion control treatment (CCT). Water systems will also need to initiate sampling at 20 percent of elementary schools and daycares annually for five years.LCRR ResourcesA number of resources are available to help water systems prepare for rule compliance. Use the QR codes below for direct access to these resources.Review GIS for relevant information (e.g., home age) and as a potential platform for inventory documentationBegin documenting materials throughout the system, prioritizing high risk areas, allowing more time for proactive replacementDevelop a plan to sequentially identify and document public and private service line materials throughout the system based on the steps above and including f ield verif ication for a subset of recordsConduct training to take advantage of ongoing maintenance activities to inspect and document service line materialsPull a representative subset of records (e.g., city ordinances, tap cards) for review12345 LSL inventories can take years to develop depending on system size, complexity, and existing records. The following steps are recommended to get a head start on LSL inventory development.Federal Register LCR RevisionsLead Service Line Replacement CollaborativeAWWA Advocacy Priorities: Managing Lead in Drinking Water

32DRINKING WATERCity of Tampa’s Suspended Ion Exchange (SIX) PilotMELANIE PICKETT , PhD (mpickett@carollo.com) LARRY ELLIOTT, PE, BCEE VINCENT HART, PE TECHNICAL EDITOR: Jess Brown, 714-593-5100 | jbrown@carollo.comCONTENT EDITOR: Nick WebberCOPY EDITOR: Youmi ParkDESIGN AND PRODUCTION: Laura Corrington, Silvia Higuera-Backlund, Matthew ParrottIN THIS ISSUE 2 Preparing for the Lead and Copper Rule Revisions 4 Greenfield Water Reclamation Plant: Process Upgrades and Operational Innovation Make for an Award-Winning CMAR Project 6 Carollo Private Sector Group - Working Closely with Industrial Clients Throughout the US 7 Making History: Nashville Metro KR Harrington and Omohundro WTP Upgrades 8 Bryant L. Bench ScholarshipNICK WEBBER, PE (nwebber@carollo.com)Greetings from your Currents Content Editor! It’s been a great pleasure to work on Currents since its inception!In this issue, we feature the Greenfield Water Reclamation Plant (WRP) in Arizona: a Construction Management At-Risk (CMAR) project that endured technical, construction—and of course—COVID-19-related challenges. All in all, the project was successfully completed at the end of last year and received multiple 2021 Project of the Year awards. Congrats to all of the Greenfield WRP team members!You’ll also read about the EPA’s Lead and Copper Rule updates, a big project win for our new Carollo office in Nashville, the 2021 Bryant L. Bench Scholarship recipient, and an introduction to the industrial client services of Carollo’s Private Sector Group (PSG).I hope you enjoy reading this issue and learning more about Carollo and the water industry. Please contact me or the primary authors if you have any questions or comments. Wishing everyone the best for the remainder of 2021!THIS ISSUE'S EDITORIALCURRENTS IN THIS ISSUEPreparing for THE LEAD AND COPPER RULE REVISIONSThe United States Environmental Protection Agency (EPA) published the Lead and Copper Rule Revisions (LCRR) in the Federal Register on January 15, 2021 (86 FR 4198). The effective date was recently delayed until December 16, 2021, allowing time for the EPA to complete its review of the rule under the new administration, and the compliance deadline has been shifted to October 16, 2024. While the EPA could change the rule, major comprehensive changes are unlikely. The delay provides water systems with the opportunity to get a head start on items that are anticipated to be required under the LCRR.CAROLINE RUSSELL, PhD, PE, BCEE (crussell@carollo.com)COMMENTARY CURRENTSRecommended Next StepsBased on Carollo’s experience helping several water systems develop a LCRR compliance strategy, the following immediate steps are recommended: Develop and adopt a 2024 strategy outlining action items to prepare for the deadline. Develop a schedule, resource plan, and budget to complete the steps outlined in the strategy. Develop a data management plan and define terminology to be used for consistency in the LSL inventory. Start developing the LSL inventory. Review lead and copper sampling sites and any changes needed to comply with the new tiering structure. Start developing a list of schools and childcare facilities and corresponding contact information for notification regarding sampling. Start developing public education materials and associated distribution lists.LCRR Compliance ElementsThe LCRR stipulates that water systems complete the following items by the compliance deadline: Ò Lead service line (LSL) inventory. Water systems must develop an inventory of the materials used in both the publicly- and privately-owned service lines. The inventory must be publicly available, and water systems must notify customers with LSLs, lead-status unknown service lines (LSUSLs), and galvanized pipes that are currently or were previously downstream of lead pipes (i.e., galvanized requiring replacement or GRR). Based on experience from water systems that have completed LSL inventories, this LCRR compliance requirement could take years to complete. Ò LSL replacement plan. Water systems must develop a LSL replacement plan, unless all service lines are confirmed to meet the EPA definition of non-lead pipe. LSL replacement frequency will depend on 90th percentile lead concentrations. Ò Updated list of lead and copper compliance sampling locations. The LCRR establishes a revised tiering structure for lead and copper tap sample locations, and water systems may need to update their sampling plans to reflect these changes. Under the LCRR, single family structures (SFS) and multi-family residences (MFRs) with LSLs must be prioritized as Tier 1 and 2 locations, respectively, for sampling. If additional locations are needed to meet the required number of samples, properties with GRR are selected next (Tier 3 locations), followed by copper pipes installed prior to 1986 (Tier 4 locations), and other representative locations (Tier 5). Ò Revised text on lead for the consumer confidence report. Additional public outreach material that water systems need to have ready to go by 2024 include: Public education (PE) materials for schools and childcare facilities. PE materials for properties with LSLs, LSUSLs, or GRR service lines. PE materials for new locations designated for lead and copper compliance sampling. Ò List of schools and childcare facilities within the service area. While the LCRR requires that sampling only be conducted in elementary schools and licensed childcare facilities, secondary schools should also be included in the list, and contacted, so that they can opt into sampling, if desired.Once the compliance deadline is reached, water systems will need to comply with the new 10 microgram per liter (µg/L) trigger level based on 90th percentile lead concentrations, and “find and fix” requirements for individual lead samples above 15 µg/L. Calcium and blended phosphate will no longer be accepted as corrosion control treatment (CCT). Water systems will also need to initiate sampling at 20 percent of elementary schools and daycares annually for five years.LCRR ResourcesA number of resources are available to help water systems prepare for rule compliance. Use the QR codes below for direct access to these resources.Review GIS for relevant information (e.g., home age) and as a potential platform for inventory documentationBegin documenting materials throughout the system, prioritizing high risk areas, allowing more time for proactive replacementDevelop a plan to sequentially identify and document public and private service line materials throughout the system based on the steps above and including f ield verif ication for a subset of recordsConduct training to take advantage of ongoing maintenance activities to inspect and document service line materialsPull a representative subset of records (e.g., city ordinances, tap cards) for review12345 LSL inventories can take years to develop depending on system size, complexity, and existing records. The following steps are recommended to get a head start on LSL inventory development.Federal Register LCR RevisionsLead Service Line Replacement CollaborativeAWWA Advocacy Priorities: Managing Lead in Drinking Water

PROJECT UPDATE CURRENTSCURRENTS PROJECT UPDATELast year, the City of Mesa, Town of Gilbert, and Town of Queen Creek, in Arizona, completed a significant expansion of their jointly owned and operated Greenfield Water Reclamation Plant (GWRP). With an added 14 million gallons per day (mgd) in treatment capacity, this improved plant can now handle up to 30 mgd annual average day flow (AADF) in liquids and 38 mgd AADF-equivalent in solids, reliably producing Class A+ reclaimed water and Class B biosolids for beneficial reuse.new and upgraded features that directly address previous O&M limitations, including an improved tertiary filtration system installed with a maintenance-friendly outside-in cloth media technology, a chlorination/de-chlorination system that replaced a costly in-channel UV disinfection system, and a new primary sludge screening system that eliminates fibrous material buildup in digested sludge.CHALLENGES ENCOUNTERED AND PROPOSED SOLUTIONS Such success underscores not only a project’s innovation and outcomes but also the challenges it overcame to exceed commitments made to the client. And a project of this scale, cost, and demand for coordination between multiple parties (municipalities, firms, and contractors), implemented during the most difficult year in recent history, was accompanied by its own set of challenges. The completion of this project marks the end of a five-year-long effort that began when, given the consistent growth and development occurring within these three municipalities, the plant was determined to be rapidly approaching its previous rated capacity of 16 mgd. In early 2015, Carollo, supported by Brown and Caldwell, initiated conceptual planning efforts followed by an 18-month detailed design phase. Carollo remained a primary consultant for procurement and construction activities that commenced in November 2017, led by the Construction Management at-Risk (CMAR) McCarthy Building Companies. The project, with a $170 million construction cost and $206 million total project cost, reached substantial completion in August 2020 and final completion in November 2020. The resulting facility is an example of sustainable design, modernized technology, and optimized operations that meets the needs of local communities, the environment, and plant staff who run operations and maintenance (O&M) day in and day out. The GWRP now boasts WATER RECLAMATION PLANT PROCESS UPGRADES AND OPERATIONAL INNOVATION MAKE FOR AN AWARD-WINNING CMAR PROJECTGREENFIELDRUSS WACHTER, PE, BCEE (rwachter@carollo.com) YOUMI PARK (ypark@carollo.com) TECHNICAL CHALLENGESOne of the first challenges the project team faced was in identifying a cost-effective path to expansion while confronting a 20 to 30 percent increase in influent wastewater strength from the facility’s original design criteria. To increase capacity and effectively meet a total nitrogen limit of 10 milligrams per liter, the plant’s existing secondary system needed three new aeration basins and four new secondary clarifiers. Understanding the financial burden this would place on the project and operations in the long run, Carollo optimized the secondary treatment process in the following ways: Ò Converted the existing conventional Modified Ludzack-Ettinger process to a 4-stage Bardenpho process. Ò Converted the existing coarse-air diffused aeration to fine-bubble diffused aeration. Ò Increased the mixed liquor recycle pumping capacity. Ò Incorporated side-stream recycle treatment by integrating a centrate and return activated sludge reaeration basin (CaRRB) process within the aeration basins. This optimized approach allowed the team to defer one aeration basin, one secondary clarifier, and three process blowers, saving upwards of $25 million in construction costs from the baseline. COVID-19 CHALLENGES Finally, the last year of construction, startup, and commissioning coincided with the COVID-19 pandemic, which threatened not only the wellbeing of workers and plant staff but also the project schedule as a result of supply-chain challenges, resource limitations, and travel and shipping restrictions. The team prioritized the safety of the 100-plus on-site personnel by developing COVID-19 safety protocols, strictly enforcing social distancing, and limiting or otherwise eliminating close-quarter gatherings. Meanwhile, to mitigate various shortages and factory delays, the team leveraged additional local vendors and suppliers as well as McCarthy’s self-perform crews. CONSTRUCTION CHALLENGES When construction began, the team faced new hurdles in expanding, rehabilitating, and continuously operating an end-of-the-line plant that was closing in on its original design capacity. The team and plant staff collaboratively developed real-time operational strategies to extract all available capacity from the GWRP’s existing infrastructure before new facilities came online. One such strategy implemented solids retention time (SRT) control in operating the aeration basins, which improved sludge settleability in the downstream secondary clarifiers and, in turn, facilitated more robust, consistent operations that still complied with nutrient permit limits. While crafting and implementing these strategies, a further complication arose: The project’s asset renewal effort identified the need to replace, reconfigure, and rewire approximately 20 aging programmable logic controllers (PLCs) and 60 variable frequency drives (VFDs). These upgrades required 130 key outages and critical tie-ins, or maintenance of plant operations (MOPOs). To systematically sequence the MOPOs and account for all constraints to operations, the CMAR led weekly MOPO-planning meetings throughout the construction phase, during which as many as 25 key stakeholders brainstormed and made operational changes to coordinate plans before every outage. As a result, the project never experienced a single unplanned outage.Recognizing the merits of this project, the Arizona Water Association, as well as the Arizona Chapters of the American Society of Civil Engineers (ASCE) and American Public Works Association (APWA), awarded the GWRP Phase III Expansion Project as their 2021 Project of the Year. With several nominations still pending, project accolades may continue to grow, both at the state and national level.CONCLUSION Despite these and other obstacles, this project was completed within contract milestones and under budget, allowing approximately $1.7 million to be allocated toward additional plant repairs. But, perhaps most importantly, the GWRP and its team committed to being a good neighbor to the local community, who participated in numerous outreach events hosted for the project. Today, stakeholders, staff, and community members of Mesa, Gilbert, and Queen Creek can all proudly call this award-winning, renewed facility their own. FEATURE STORY CURRENTS5CURRENTS FEATURE STORY44444444

PROJECT UPDATE CURRENTSCURRENTS PROJECT UPDATELast year, the City of Mesa, Town of Gilbert, and Town of Queen Creek, in Arizona, completed a significant expansion of their jointly owned and operated Greenfield Water Reclamation Plant (GWRP). With an added 14 million gallons per day (mgd) in treatment capacity, this improved plant can now handle up to 30 mgd annual average day flow (AADF) in liquids and 38 mgd AADF-equivalent in solids, reliably producing Class A+ reclaimed water and Class B biosolids for beneficial reuse.new and upgraded features that directly address previous O&M limitations, including an improved tertiary filtration system installed with a maintenance-friendly outside-in cloth media technology, a chlorination/de-chlorination system that replaced a costly in-channel UV disinfection system, and a new primary sludge screening system that eliminates fibrous material buildup in digested sludge.CHALLENGES ENCOUNTERED AND PROPOSED SOLUTIONS Such success underscores not only a project’s innovation and outcomes but also the challenges it overcame to exceed commitments made to the client. And a project of this scale, cost, and demand for coordination between multiple parties (municipalities, firms, and contractors), implemented during the most difficult year in recent history, was accompanied by its own set of challenges. The completion of this project marks the end of a five-year-long effort that began when, given the consistent growth and development occurring within these three municipalities, the plant was determined to be rapidly approaching its previous rated capacity of 16 mgd. In early 2015, Carollo, supported by Brown and Caldwell, initiated conceptual planning efforts followed by an 18-month detailed design phase. Carollo remained a primary consultant for procurement and construction activities that commenced in November 2017, led by the Construction Management at-Risk (CMAR) McCarthy Building Companies. The project, with a $170 million construction cost and $206 million total project cost, reached substantial completion in August 2020 and final completion in November 2020. The resulting facility is an example of sustainable design, modernized technology, and optimized operations that meets the needs of local communities, the environment, and plant staff who run operations and maintenance (O&M) day in and day out. The GWRP now boasts WATER RECLAMATION PLANT PROCESS UPGRADES AND OPERATIONAL INNOVATION MAKE FOR AN AWARD-WINNING CMAR PROJECTGREENFIELDRUSS WACHTER, PE, BCEE (rwachter@carollo.com) YOUMI PARK (ypark@carollo.com) TECHNICAL CHALLENGESOne of the first challenges the project team faced was in identifying a cost-effective path to expansion while confronting a 20 to 30 percent increase in influent wastewater strength from the facility’s original design criteria. To increase capacity and effectively meet a total nitrogen limit of 10 milligrams per liter, the plant’s existing secondary system needed three new aeration basins and four new secondary clarifiers. Understanding the financial burden this would place on the project and operations in the long run, Carollo optimized the secondary treatment process in the following ways: Ò Converted the existing conventional Modified Ludzack-Ettinger process to a 4-stage Bardenpho process. Ò Converted the existing coarse-air diffused aeration to fine-bubble diffused aeration. Ò Increased the mixed liquor recycle pumping capacity. Ò Incorporated side-stream recycle treatment by integrating a centrate and return activated sludge reaeration basin (CaRRB) process within the aeration basins. This optimized approach allowed the team to defer one aeration basin, one secondary clarifier, and three process blowers, saving upwards of $25 million in construction costs from the baseline. COVID-19 CHALLENGES Finally, the last year of construction, startup, and commissioning coincided with the COVID-19 pandemic, which threatened not only the wellbeing of workers and plant staff but also the project schedule as a result of supply-chain challenges, resource limitations, and travel and shipping restrictions. The team prioritized the safety of the 100-plus on-site personnel by developing COVID-19 safety protocols, strictly enforcing social distancing, and limiting or otherwise eliminating close-quarter gatherings. Meanwhile, to mitigate various shortages and factory delays, the team leveraged additional local vendors and suppliers as well as McCarthy’s self-perform crews. CONSTRUCTION CHALLENGES When construction began, the team faced new hurdles in expanding, rehabilitating, and continuously operating an end-of-the-line plant that was closing in on its original design capacity. The team and plant staff collaboratively developed real-time operational strategies to extract all available capacity from the GWRP’s existing infrastructure before new facilities came online. One such strategy implemented solids retention time (SRT) control in operating the aeration basins, which improved sludge settleability in the downstream secondary clarifiers and, in turn, facilitated more robust, consistent operations that still complied with nutrient permit limits. While crafting and implementing these strategies, a further complication arose: The project’s asset renewal effort identified the need to replace, reconfigure, and rewire approximately 20 aging programmable logic controllers (PLCs) and 60 variable frequency drives (VFDs). These upgrades required 130 key outages and critical tie-ins, or maintenance of plant operations (MOPOs). To systematically sequence the MOPOs and account for all constraints to operations, the CMAR led weekly MOPO-planning meetings throughout the construction phase, during which as many as 25 key stakeholders brainstormed and made operational changes to coordinate plans before every outage. As a result, the project never experienced a single unplanned outage.Recognizing the merits of this project, the Arizona Water Association, as well as the Arizona Chapters of the American Society of Civil Engineers (ASCE) and American Public Works Association (APWA), awarded the GWRP Phase III Expansion Project as their 2021 Project of the Year. With several nominations still pending, project accolades may continue to grow, both at the state and national level.CONCLUSION Despite these and other obstacles, this project was completed within contract milestones and under budget, allowing approximately $1.7 million to be allocated toward additional plant repairs. But, perhaps most importantly, the GWRP and its team committed to being a good neighbor to the local community, who participated in numerous outreach events hosted for the project. Today, stakeholders, staff, and community members of Mesa, Gilbert, and Queen Creek can all proudly call this award-winning, renewed facility their own. FEATURE STORY CURRENTS5CURRENTS FEATURE STORY44444444

PROJECT UPDATE CURRENTSCURRENTS PSG HIGHLIGHTCarollo’s Private Sector Group (PSG) has been working closely with clients in virtually every industry to successfully manage their greatest water and wastewater challenges. The Carollo PSG team supports our clients to maximize and optimize their water resources, ensure their compliance with regulatory requirements, reduce their water footprint, minimize their associated treatment costs, and enhance their corporate sustainability and climate resilience—all while minimizing the impacts to their core business operations and improving their bottom line.General Industrial Pharmaceuticals, aerospace, textiles, pulp and paper, etc.High TechSemiconductors, data centersFood and BeverageNative AmericanMiningPowerOil and GasAirportsFederal/Government SUSTAINABLE WATER SUPPLYCOMPLIANCE AND PERMITTINGWATER REUSESPECIALIZED WASTE/BRINE TREATMENTEMERGING CONTAMINANTS:Microplastics, PFASPRIVATE SECTOR GROUP SERVICE LINESMARKET SECTORSCarollo’s PSG team is cultivating a sustainable environment by harnessing our employees’ passion and creative energy to implement innovative solutions that help our clients optimize their processes, enhance reuse and recovery, increase resiliency and maximize their water resources. What’s the result? A healthier planet and an improved bottom line for our clients. As an engineering firm exclusively focused on water, helping our clients address current drinking water, wastewater, and reuse regulations, and preparing them for any future compliance implications is an important component of our work. Our team uses our regulatory expertise and relationships across the country to assist our industrial clients in addressing their unique permitting and compliance challenges associated with all aspects of their operations.Water reuse is the future for a sustainable world. With climate change, water restrictions, and other issues facing the industry, our clients must look toward recycled water to meet their needs. Carollo is a leader in engineering water reuse systems, with a long history of supporting water reuse planning and implementation throughout the US. While treating industrial waste for reuse provides unique challenges, we continue to develop and implement safe and effective solutions to treat and recycle highly variable industrial water streams to support continued growth and technological advancement for our clients.Our team of wastewater treatment experts develops innovative treatment solutions for the diverse waste streams generated by our industrial clients—from organics and metals to hazardous wastes and other unique constituents specific to each sector. In addition, as water reuse expands in both the public and private sectors, so does the use of reverse osmosis (RO), which produces a brine waste stream that must be appropriately managed. Brine treatment, from minimization to full zero-liquid discharge systems, is an ever-expanding market, with a constant push to lower the cost and produce residuals with beneficial reuse potential. Our team has emerged as an industry leader in developing cost-effective brine solutions for our industrial clients in all market sectors. Microplastics and per- and polyfluoroalkyl substances (PFAS) are a significant are a significant concern to our industrial clients. Carollo is a leader in the field of microplastics in water andwastewater—having developed quantification techniques, monitoring initiatives, and mitigation strategies. Additionally, we have experience in removing PFAS from water through participating in innovative research, piloting, and implementing full-scale treatment solutions to remove these contaminants. SUSTAINABLE WATER SUPPLYCOMPLIANCE AND PERMITTINGWATER REUSESPECIALIZED WASTE/BRINE TREATMENTEMERGING CONTAMINANTS: MICROPLASTICS AND PFAS7 Every project that we execute for our clients is special. Certain projects that we deliver are career defining. And, on very rare occasions, we may have an opportunity to be part of a project that is truly iconic. The project that the Carollo team recently won with Metro Water Services in Nashville, TN, is iconic.” – Jim MeyerhoferMAKING HISTORYJIM MEYERHOFER, PE (jmeyerhofer@carollo.com) JENNA MANUSZAK, PE (jmanuszak@carollo.com) Carollo continues its east coast expansion with an important project win in Tennessee. The Nashville Metro Water Services (Metro) project builds on the firm’s successful pilot study that laid the groundwork for the design.Carollo opened a Nashville office in August 2020, and has since hired Joe Whitson as the Nashville local leader and welcomed five local staff members, and strategically teamed with several of Metro’s preferred consultants.Nashville Metro KR Harrington and Omohundro WTP UpgradesA STRONG HISTORY WITH AN EYE ON THE FUTUREMetro operates two large (>100 mgd) drinking water treatment facilities—Omohundro and KR Harrington, built in 1889 and 1978, respectively. The Omohundro Water Treatment Plant is on the National Register of Historic Places (its main building exterior pictured above and filter gallery pictured below). Given the age of these facilities, they require significant upgrades and modernization. Carollo will perform design and construction of raw and intermediate pumping stations, pre-treatment and filter improvements, chemical feed upgrades, new clearwell facilities, and many other enhancements.The crown jewel of the work will be adding post-filter granular activated carbon (GAC) adsorption facilities at both plants to provide superior taste and odor control and management of disinfection by-products.PROJECT PATHWAY AND CHALLENGES ALONG THE WAYAn important challenge for our team is to make extensive modifications to these plants while maintaining desired finished water production levels and water quality objectives. The project will be delivered by CMAR and will play out over the next seven years.PROJECT BENEFITSThis important project will achieve Metro’s rigorous water quality goals, so they can continue to provide safe drinking water to Nashville area residents and visitors for another 100 years.6 7WHAT’S NEW CURRENTSCAROLLO PRIVATE SECTOR GROUP Working Closely with Industrial Clients Throughout the USDAVE SOBECK, PE (dsobeck@carollo.com) PETER BOKOR, PE (pbokor@carollo.com)

PROJECT UPDATE CURRENTSCURRENTS PSG HIGHLIGHTCarollo’s Private Sector Group (PSG) has been working closely with clients in virtually every industry to successfully manage their greatest water and wastewater challenges. The Carollo PSG team supports our clients to maximize and optimize their water resources, ensure their compliance with regulatory requirements, reduce their water footprint, minimize their associated treatment costs, and enhance their corporate sustainability and climate resilience—all while minimizing the impacts to their core business operations and improving their bottom line.General Industrial Pharmaceuticals, aerospace, textiles, pulp and paper, etc.High TechSemiconductors, data centersFood and BeverageNative AmericanMiningPowerOil and GasAirportsFederal/Government SUSTAINABLE WATER SUPPLYCOMPLIANCE AND PERMITTINGWATER REUSESPECIALIZED WASTE/BRINE TREATMENTEMERGING CONTAMINANTS:Microplastics, PFASPRIVATE SECTOR GROUP SERVICE LINESMARKET SECTORSCarollo’s PSG team is cultivating a sustainable environment by harnessing our employees’ passion and creative energy to implement innovative solutions that help our clients optimize their processes, enhance reuse and recovery, increase resiliency and maximize their water resources. What’s the result? A healthier planet and an improved bottom line for our clients. As an engineering firm exclusively focused on water, helping our clients address current drinking water, wastewater, and reuse regulations, and preparing them for any future compliance implications is an important component of our work. Our team uses our regulatory expertise and relationships across the country to assist our industrial clients in addressing their unique permitting and compliance challenges associated with all aspects of their operations.Water reuse is the future for a sustainable world. With climate change, water restrictions, and other issues facing the industry, our clients must look toward recycled water to meet their needs. Carollo is a leader in engineering water reuse systems, with a long history of supporting water reuse planning and implementation throughout the US. While treating industrial waste for reuse provides unique challenges, we continue to develop and implement safe and effective solutions to treat and recycle highly variable industrial water streams to support continued growth and technological advancement for our clients.Our team of wastewater treatment experts develops innovative treatment solutions for the diverse waste streams generated by our industrial clients—from organics and metals to hazardous wastes and other unique constituents specific to each sector. In addition, as water reuse expands in both the public and private sectors, so does the use of reverse osmosis (RO), which produces a brine waste stream that must be appropriately managed. Brine treatment, from minimization to full zero-liquid discharge systems, is an ever-expanding market, with a constant push to lower the cost and produce residuals with beneficial reuse potential. Our team has emerged as an industry leader in developing cost-effective brine solutions for our industrial clients in all market sectors. Microplastics and per- and polyfluoroalkyl substances (PFAS) are a significant are a significant concern to our industrial clients. Carollo is a leader in the field of microplastics in water andwastewater—having developed quantification techniques, monitoring initiatives, and mitigation strategies. Additionally, we have experience in removing PFAS from water through participating in innovative research, piloting, and implementing full-scale treatment solutions to remove these contaminants. SUSTAINABLE WATER SUPPLYCOMPLIANCE AND PERMITTINGWATER REUSESPECIALIZED WASTE/BRINE TREATMENTEMERGING CONTAMINANTS: MICROPLASTICS AND PFAS7 Every project that we execute for our clients is special. Certain projects that we deliver are career defining. And, on very rare occasions, we may have an opportunity to be part of a project that is truly iconic. The project that the Carollo team recently won with Metro Water Services in Nashville, TN, is iconic.” – Jim MeyerhoferMAKING HISTORYJIM MEYERHOFER, PE (jmeyerhofer@carollo.com) JENNA MANUSZAK, PE (jmanuszak@carollo.com) Carollo continues its east coast expansion with an important project win in Tennessee. The Nashville Metro Water Services (Metro) project builds on the firm’s successful pilot study that laid the groundwork for the design.Carollo opened a Nashville office in August 2020, and has since hired Joe Whitson as the Nashville local leader and welcomed five local staff members, and strategically teamed with several of Metro’s preferred consultants.Nashville Metro KR Harrington and Omohundro WTP UpgradesA STRONG HISTORY WITH AN EYE ON THE FUTUREMetro operates two large (>100 mgd) drinking water treatment facilities—Omohundro and KR Harrington, built in 1889 and 1978, respectively. The Omohundro Water Treatment Plant is on the National Register of Historic Places (its main building exterior pictured above and filter gallery pictured below). Given the age of these facilities, they require significant upgrades and modernization. Carollo will perform design and construction of raw and intermediate pumping stations, pre-treatment and filter improvements, chemical feed upgrades, new clearwell facilities, and many other enhancements.The crown jewel of the work will be adding post-filter granular activated carbon (GAC) adsorption facilities at both plants to provide superior taste and odor control and management of disinfection by-products.PROJECT PATHWAY AND CHALLENGES ALONG THE WAYAn important challenge for our team is to make extensive modifications to these plants while maintaining desired finished water production levels and water quality objectives. The project will be delivered by CMAR and will play out over the next seven years.PROJECT BENEFITSThis important project will achieve Metro’s rigorous water quality goals, so they can continue to provide safe drinking water to Nashville area residents and visitors for another 100 years.6 7WHAT’S NEW CURRENTSCAROLLO PRIVATE SECTOR GROUP Working Closely with Industrial Clients Throughout the USDAVE SOBECK, PE (dsobeck@carollo.com) PETER BOKOR, PE (pbokor@carollo.com)

CURRENTS PROJECT UPDATE8CURRENTS SPOTLIGHTCarollo awarded its sixth Bryant L. Bench Scholarship to RAJUAN NELSON during the prestigious Scholarship Recognition Event on June 8, 2021. The Bryant L. Bench Scholarship was launched in honor of Carollo’s Water Practice Director, Bryant Bench, whose innovative treatment concepts helped improve drinking water quality across the country. Applicants for this scholarship must be pursuing a master’s degree in a water engineering-related field. The scholarship is a one-time $10,000 award that students can use to complete or further their education in their chosen field. Rajuan recently received his master’s degree in environmental engineering from the University of Southern California. He has focused his research on green energy sources to fuel energy-intensive desalination techniques. Additionally, Rajuan served three internship periods with Carollo, which started in June 2018, and continued through 2019 and 2020. He plans to pursue a doctoral degree on membrane desalination to acquire new research skills and knowledge in the field from renowned research leaders on the topic.Congratulations, Rajuan!SCHOLARSHIPTAG US, LIKE US, AND SHARE US!Use your QR scanner to link directly to our sites, and you can follow us from there.WITH SUSTAINABILITY IN MIND, OUR HARD COPIES OF CURRENTS ARE PRINTED WITH SOY INK ON FSC CERTIFIED 10% POST-CONSUMER WASTE RECYCLED PAPER; HOWEVER, IF YOU WOULD LIKE TO RECEIVE AN E-COPY INSTEAD, PLEASE LET US KNOW BY CONTACTING CURRENTS@CAROLLO.COM. THANK YOU!